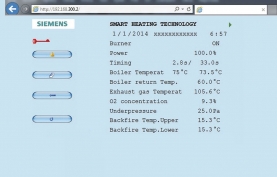

| SMART BOILERS OPERATING DATA |

| Marking |

|

200 |

| Nominal power Pn |

kW |

199 |

| Partial load (power) Pp |

kW |

50 |

| Boiler efficiency at Pn |

% |

>95 |

| Boiler class |

|

5 |

| Water volume |

l |

460 |

Diameter of water

connection |

“ |

3 |

| Diameter of water connection |

DN |

80 |

Hydraulic-pressure drop

of the boiler

at the temperature fall 20° |

mbar

|

80

|

| Boiler temperature |

°C |

60–90° |

| Minimal temperature of returnable water |

°C |

55 |

| Maximal operational pressure |

bar |

3,5 |

| Test pressure |

bar |

6,5 |

| Temperature of furnace |

°C |

|

| Pressure of furmace |

mbar |

-0,04 |

| Required draught of the chimney |

mbar |

0,2 |

| Requirement for the forced draught |

|

Yes |

| Combustion temperature at Pn |

°C |

104,9 |

| Combustion temperature at Pp |

°C |

72,4 |

| Diameter of flue gas duct |

mm |

220 |

| Diameter of chimney |

mm |

250 |

| Wood pellets – C1 |

Tested

fuel |

D6, M10, A1,5, DU90,0 |

| Wood chips – B1 |

P45, M30, A3.0 |

| Electrical connection |

|

3+N+PE 50Hz 230/400V TN-C-S |

| Conveyor engine |

W |

550 |

| Feeding auger engine |

W |

550 |

| Exchanger cleaning engine (s) |

W

|

550

|

| Ash-removing engine |

W |

550 |

| Fan of primary air |

W |

66 |

| Fan of secondary air 1 |

W |

66 |

| Fan of secondary air 2 |

W |

66 |

| Chimney exhaust fan |

W |

300 |

| Electrical ignition |

W |

1600 |

| Separation flap valve |

W |

6,5 |

|

| Wood pellets |

Wood chips |

| Rated |

Minimum |

Rated |

Minimum |

| Rated heat capacity |

kW |

199 |

199 |

199 |

199 |

Combustion product

temperature |

°C |

96,1 |

73,1 |

104,9 |

72,4 |

| Fuel consumption |

kg/hour |

42,60 |

12,48 |

50,60 |

14,50 |

| Input water temperature |

°C |

57,8 |

67,2 |

55,0 |

71,3 |

| Outlet water temperature |

°C |

73,0 |

82,6 |

77,1 |

79,0 |

| Cooling water temperature |

°C |

11,1 |

7,8 |

10,6 |

11,5 |

| Cooling water flow rate |

m3/hod |

2,695 |

0,650 |

2,673 |

0,755 |

| Draught behind boiler |

Pa |

130,0 |

30,0 |

130,0 |

30,0 |

| Ambient temperature |

°C |

25,2 |

24,9 |

24,1 |

26,2 |

| Relative air humidity |

% |

42,3 |

41,1 |

41,0 |

40,0 |

| Barometric pressure |

kPa |

98,92 |

98,95 |

99,07 |

99,07 |

| Oxygen O2 |

% |

8,02 |

12,71 |

8,02 |

12,71 |

| Carbon dioxide CO2 |

% |

11,79 |

7,53 |

11,79 |

7,53 |

| Carbon monoxide CO |

ppm |

58 |

181 |

58 |

181 |

| Higher hydrocarbons OGC |

ppm |

7 |

4 |

7 |

4 |

| Nitrogen dioxides Nox |

ppm |

65 |

38 |

65 |

38 |

| Dust |

mg/m3 |

29 |

18 |

51 |

44 |

| Carbon monoxide CO |

mg/m3 |

62 |

301 |

112 |

244 |

| Higher hydrocarbons OGC |

mg/m3 |

10 |

8 |

2 |

4 |

| Nitrogen dioxides Nox |

mg/m3 |

113 |

102 |

151 |

120 |

| Dust |

mg/m3 |

25 |

25 |

44 |

51 |

| Mass flow rate gases |

kg/sec |

0,155 |

0,053 |

0,148 |

0,066 |

| Stoichiometric oxygen value |

m3/kg |

0,949 |

0,948 |

0,848 |

0,848 |

| Stoichiometric air value |

m3/kg |

4,520 |

4,512 |

4,037 |

4,036 |

| Stoichiometric volumeof dry combustion products |

m3/kg |

4,445 |

4,438 |

3,949 |

3,948 |

| Stoichiometric air multiple |

|

1,61 |

2,51 |

1,60 |

2,50 |

| Volume of dry combustion products, actual |

m3/kg |

7,411 |

11,553 |

6,435 |

10,048 |

| Volume of H2O in the combustion air |

m3/kg |

0,101 |

0,150 |

0,081 |

0,140 |

| Volume of H2O in the combustion produts |

m3/kg |

0,867 |

0,916 |

0,956 |

1,015 |

| Maximum volume CO2 |

% |

19,60 |

19,66 |

19,22 |

19,22 |

| Loss of sensible heat of combustion products (chimney) |

% |

4,5 |

4,5 |

5,3 |

4,5 |

| Loss of gas underburning |

% |

0,0 |

0,2 |

0,0 |

0,2 |

| Loss of mechanical underburning |

% |

0,1 |

0,2 |

0,0 |

0,1 |

| Loss of heat transfer into the environment |

% |

0,6 |

0,9 |

0,6 |

0,7 |

| Total loss |

% |

5,2 |

5,8 |

6,0 |

5,4 |

| Efficiency – indirect method |

% |

94,8 |

94,2 |

94,0 |

94,6 |

| Heat input |

kW |

203,3 |

59,5 |

216,8 |

62,1 |

| Heat capacity |

kW |

193,7 |

56,6 |

206,2 |

59,3 |

| Uncertainty of determining heat capacity |

% +/- |

8,1 |

2,4 |

8,7 |

2,5 |

| Efficiency – direct method |

% |

95,3 |

95,1 |

95,1 |

95,5 |

| Capacity / rated output |

% |

97,3 |

28,4 |

103,6 |

29,8 |

|